Corrugated Steel Ducts

DESCRIPTION

Corrugated steel ducts are used to house and protect post-tensioning tendons inside concrete structures. Made from galvanized steel, they provide excellent strength and bonding with concrete.

KEY FEATURES:

Spiral-wound lock-forming galvanized steel (G90 standard).

4-ply stitch seam for maximum leak-tightness and rigidity.

Bundled packaging for easy handling and installation.

Tested for lateral load, flexural behavior, water tightness, and tensile resistance.

application:

Bridges, towers, high-rise buildings, and large-span slabs

Smooth Steel Ducts

DESCRIPTION

Flat ducts manufactured from smooth galvanized steel, designed for uniform stress transfer and easy integration in post-tensioning systems.

KEY FEATURES:

Produced in 0.35 mm galvanized steel (150 g/m² zinc coating).

Bundled in sets of 5 ducts for efficient site handling.

High rigidity with controlled deflection under load.

Meets international norms: BS EN 523 & ASTM standards.

application:

labs, beams, and where flat duct profiles are required for multiple tendons.

HDPE Corrugated Ducts

DESCRIPTION

Thick-walled High-Density Polyethylene (HDPE) ducts provide superior corrosion protection, especially in harsh environments such as wastewater plants, acid tanks, silos, and areas exposed to de-icing salts.

KEY FEATURES:

Long-term secondary corrosion protection.

High flexibility, reducing friction losses up to 41% compared to steel ducts.

Chemically stable, non-reactive with concrete and steel.

Available in round ducts from 50 mm up to 200 mm.

application:

Aggressive or corrosive environments, durable infrastructure projects, bridges, and special structures.

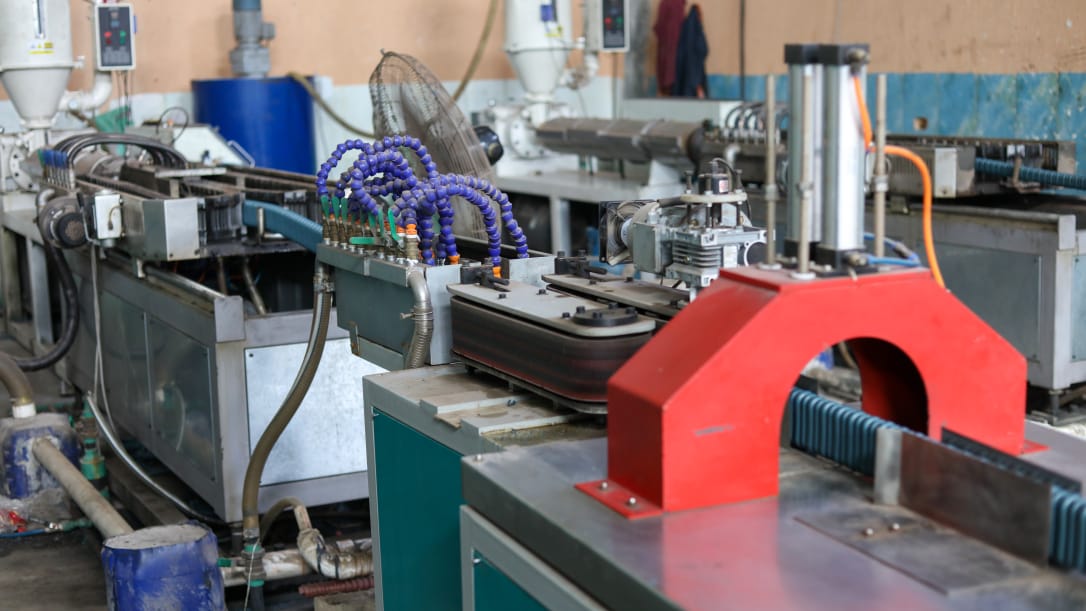

Manufacturing